Cover Options – HDPE Concrete Pits

Hydro Construction Products can offer a large range of Cover Options – HDPE Pits and Extension Risers designed to be used in the Australian and New Zealand Electrical and Communications cabling markets.

Cement Concrete (Class A)

Cement Concrete Covers are manufactured using 40MPa Concrete, further strength has been achieved with the addition of 4mm reinforcing throughout each cover. ‘Electrical’,’Communications’ or ‘Telstra’ Markings are cast into the cover during the manufacturing process to identify the contents of the pit, alternatively the covers can be left unmarked. To assist in lifting the covers to/from the pit, each cover has lifting holes in 2 sides that fit a standard lifting key tool. To limit damage that may occur to the back of the cover from repetitive lifting, a stainless steel backing plate is fitted to underside of lifting holes. For larger pits that require more than 1 cover, a Crossbar will need to be used to support the covers.

Galvanised Cast Iron Lids (Class B)

Galvanised Cast Iron Covers are manufactured to achieve a Class B Load Rating. Unlike Galvanised Mild Steel the Galvanised Cast Iron Covers are one single piece cast with no joins or seams. Brass Identification Marking Plates can be secured to the cover to identify the contents of the pit, alternatively they can be left unmarked. To assist in lifting the covers to/from the pit, each cover has lifting holes in 2 sides that fit a standard lifting key tool. In addition the covers also include a tamper proof box fitted to the underside of each lifting hole which allows for foreign objects or rodents from entering the pit causing expensive damage. For larger pits that require more than 1 cover, a Crossbar will need to be used to support the covers. Covers can be secured to the pit with the addition of a Locking Mechanism

Galvanised Cast Iron Lids (Class B) MRD

The Galvanised Cast Iron Lids used in Main Roads applications are manufactured as above with the addition of a Non-Slip, Non-Conductive MRD Approved Coating in accordance with AS3996:2006 to meet the Class B Load Classification and AS4586 / AS/NZS 4463 for the Non-Slip Surface. Pits and Lids used in Main Roads Applications have been Approved for use and certificates can be provided if required. Custom made steel / cast iron covers are manufactured in accordance with AS3996:2006 Load Rating.

Cross Bar – Cast Iron Cross Bar

Crossbars are supplied where there are multiple covers required for a pit. Crossbars are manufactured from Cast Iron and can be supplied with/without the MRD Spec coating.

Cover Options – Polymer Concrete Pits

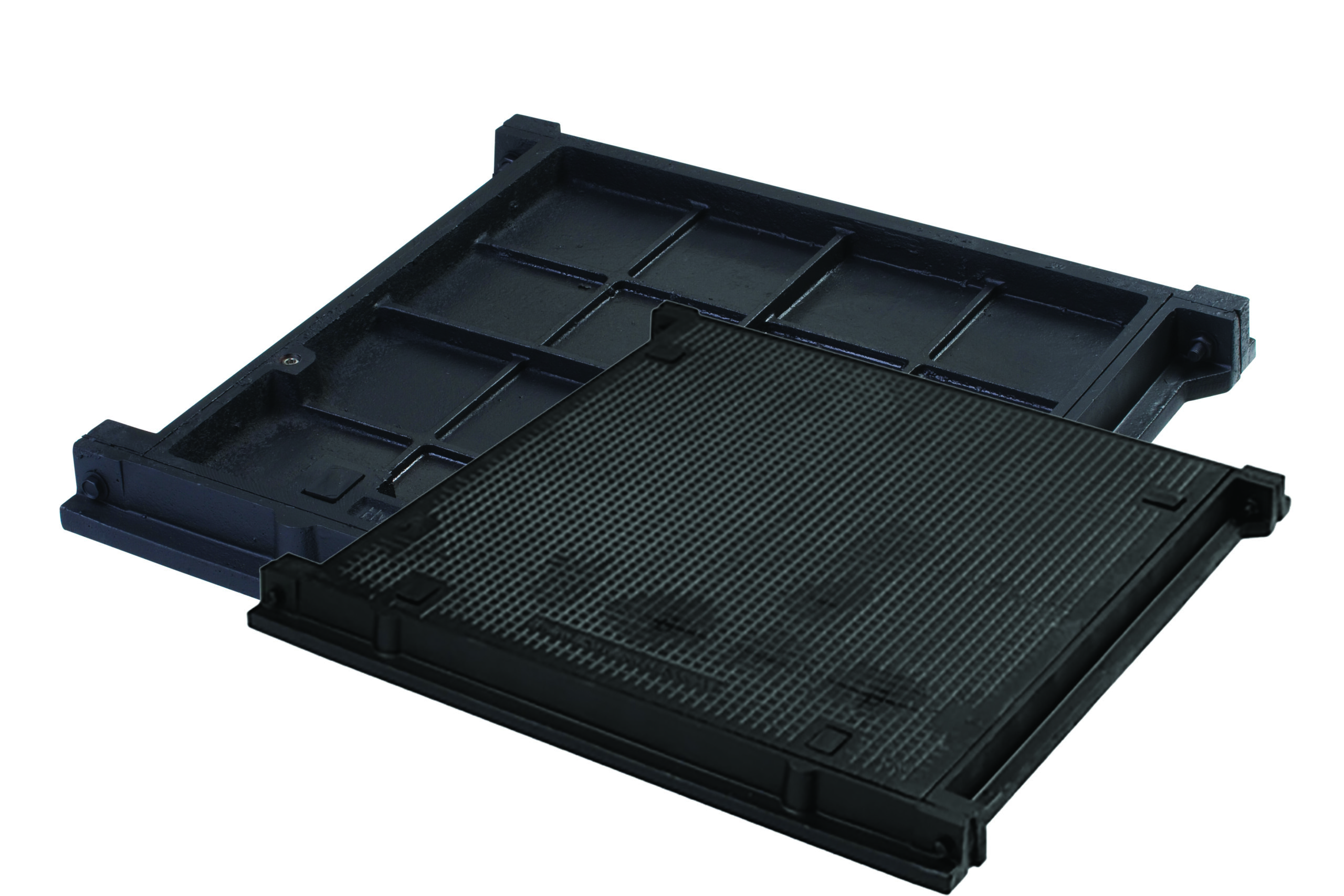

Galvanised Chequer Plate Steel Covers Class A and C

Galvanised Chequer Plate Steel Covers sit into a frame that is cast above the polymer pit to restrict the load transferring. Gal Chequer Plate Steel Covers can be locked using a M8 Thread Bolt.

Ductile Iron Covers – Solid Top Class B and D (Class G on Request)

Manufactured from Ductile Iron with a solid top, these covers are designed to sit inside a frame that is cast above the top of the polymer pit to restrict the load transferring. Solid Top covers can be locked using a M8 Thread Bolt.

Ductile Iron Covers – Solid Top Class B and D (Class G on Request)

Manufactured from Ductile Iron with a recessed top, these covers are designed to sit inside a frame that is cast above the top of the polymer pit to restrict the load transferring. Coloured Concrete, Aggregate or Bitumen can be poured into the cover to match the surroundings of the environment. The Covers are not suitable to be used with pavers. For aesthetic purposes a brass or stainless edge can be supplied on the Class B Covers only. Recessed covers can be locked using a M8 Thread Bolt.

Special Made to Order Covers, Contact Hydro for details

A large range of covers can be supplied or manufactured to suit various applications or requirements of projects. Covers can be manufactured from Galvanised Mild Steel, Galvanised Checker Plate Steel and Cast Iron as Solid Top Drop In or Recessed. Some covers can also be supplied with a locking mechanism where required. Where there is a requirement for pits to be installed, special manufactured covers can be supplied to specification and installed on top of in-situ pits. For more information contact Hydro Construction Products. Multipart covers are available upon request.

Secure Locking

A unique feature of the Hydro Polymer Pits is the ability to utilise the M8 Galvanised Thread located in the corners of the lid recess. With the addition of a M8 Threaded Bolt the Covers can be to securily locked down to the pit. The M8 Galvanised Thread can also be utilised to assist in lifting with the addition of lifting hooks/chains.

Pit Marking Cover Identification

The contents of an electrical pit are identified by what markers are visible on the cover. Covers are generally marked ‘Electrical’, ‘Communications’ or ‘Telstra’, but can also be left blank and have special markings or plates with company logos. All Gal Chequer Plate and Ductile Iron Cast Iron covers can have a brass plate engraved with the markings secured to the cover.

For more information on this product or any of Hydro’s Products, please contact our expert team.